Honorable Mention

Wool Mill in Piedmont Region

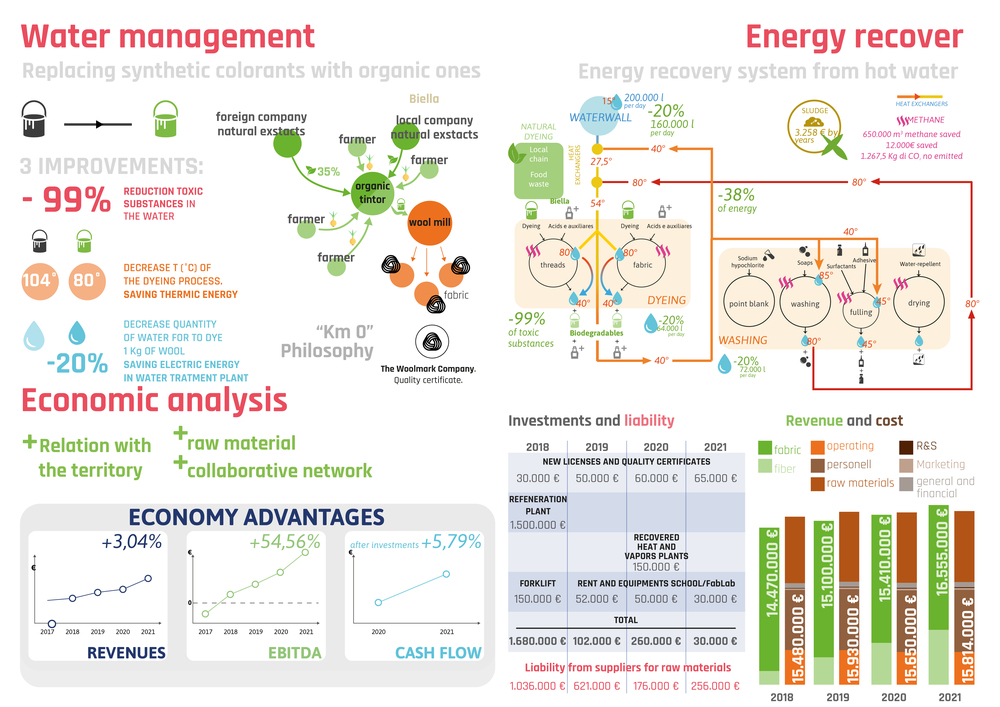

Design textile productive system based on quality flows. New business involving local stakeholders.

Solution

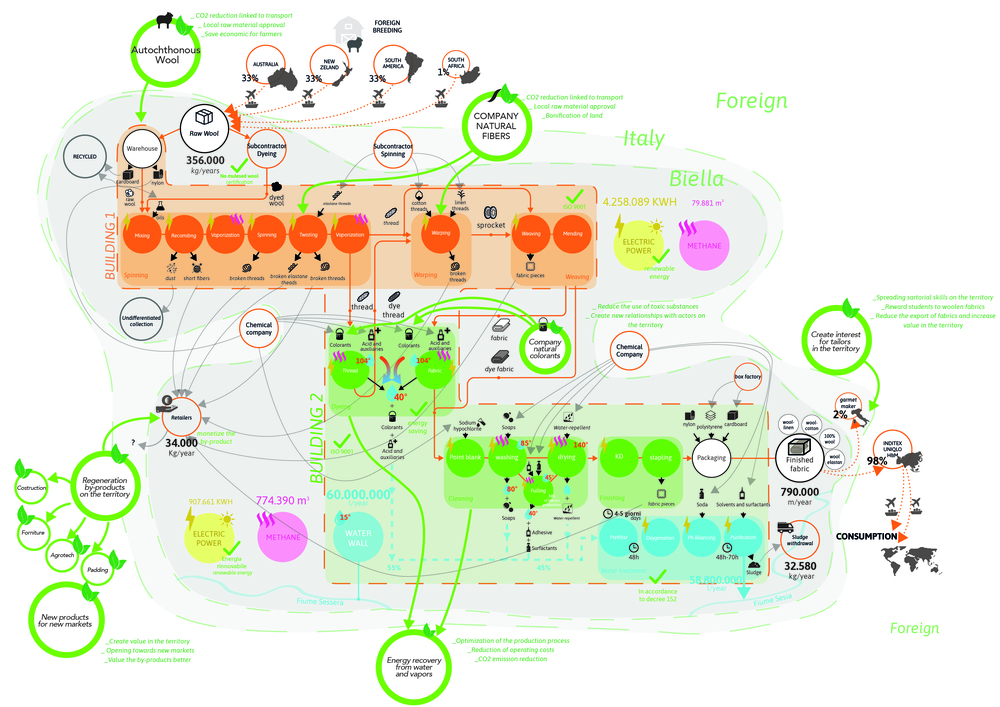

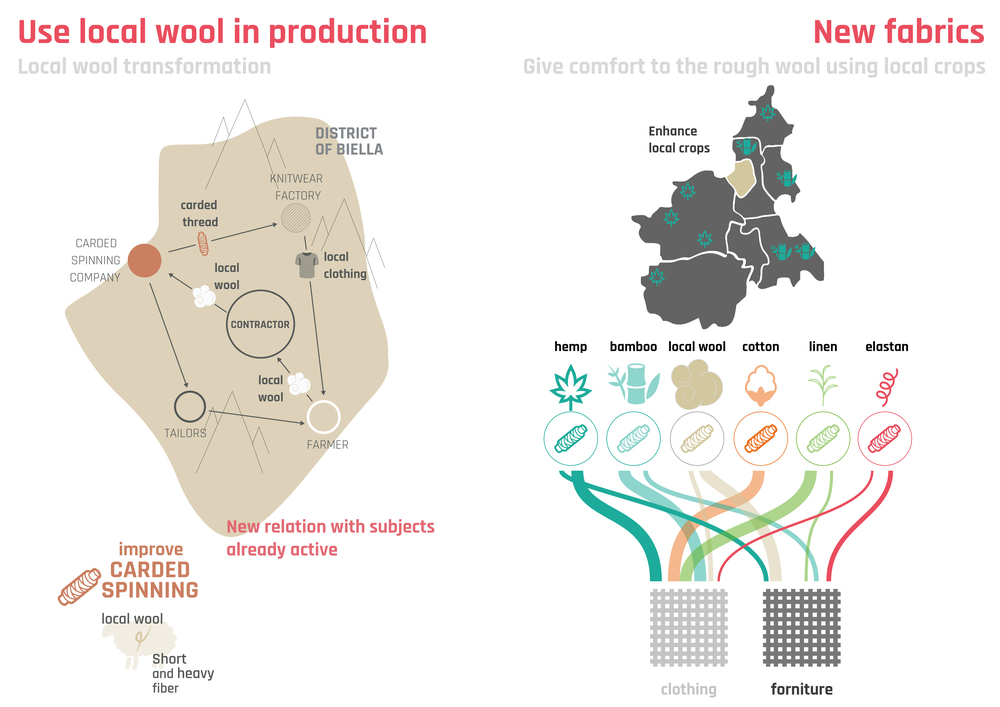

Design system based on quality of both input and output flows. Different solutions solved problems of textile industry in the Region, creating new business involving local stakeholders. Reduce carbon footprint increasing use of local wool, reducing 40% wool imported from other continents. Mix local wool with local fibers such as hemp and bamboo to improve fabric quality and enhance these crops. Create link between enterprises, technical college and artisanal tailoring to improve their know-how.

Project Description

Than a holistic diagnosis, we identify problems about textile industry. We delve into the topic working with Comero S.p.a.. The holistic system promotes the increase of local sales by decreasing the transportation process and generating greater economic and industrial flow in the region; and as a final intervention the foundation of a school as a creative network between companies and students of the textile sector to generate learning practices and waste valorization for the development of new markets and a common welfare. Working with stakeholder help us to analize economics feasibility of our solutions.

Overview of the Solution

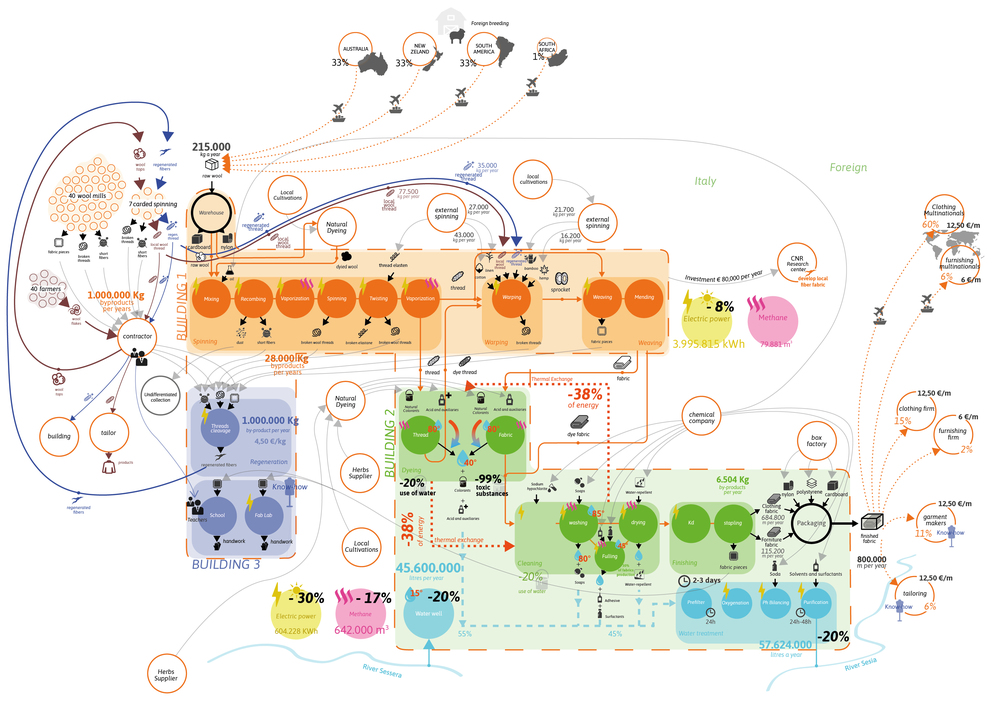

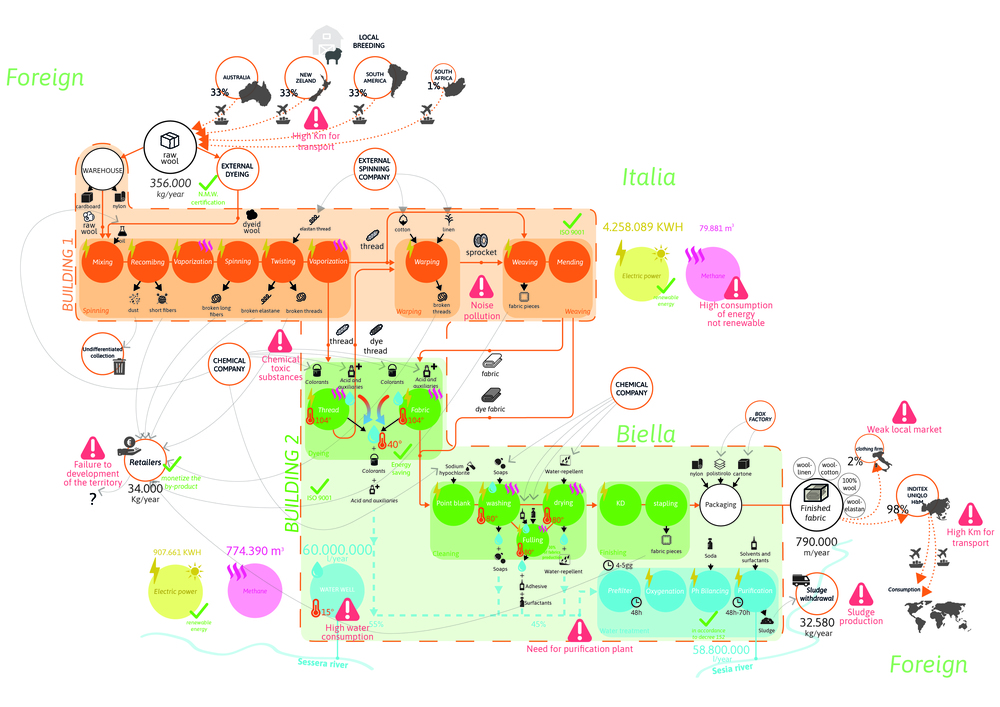

Through a holistic diagnosis in Piedmont Region, we can work with awareness on the scenario, generating sustainable solutions for the territory and the actors who live here. We analyzed the Region from different point of view: Economic, Demographic, Geographic, Cultural, Education and Disposal of Waste, focusing on regulations in force and bureaucratic constraints, in order to create distributed value with zero impact on the environment. Then, we studied all the production chain of our stakeholders and all the matter and energy flows, both input and output. We studied Comero’s Balance Sheet, in order to guarantee the economic sustainability of the solutions that we would have proposed to stakeholders.

By crossing all the results of our analysis, we generated concepts with positive outcomes in the area. Our solutions includes increasing the use of local wool, reducing 40% import from other continents, mixed with fibers such as hemp and bamboo to improve its quality, changing the chemical dyes by natural dyes produced in the region, using 99% less of harmful substances, even though these increase the investment costs and technology, then it is balanced by the savings generated, because the amount of water needed for the washing phase of the textile can be reduced up to 30% with the use of natural dyes, and the waste is less polluting for the rivers of the region; so the amount of sludge that is discarded is lower and can be processed for the construction industry and other processes, as well as textile waste.

Another type of factor to solve is the use of energy, generating an exchange for the reuse of water temperature to heat recovery by the boilers steam that allows a reduction in methane consumption. This holistic system promotes the increase of local sales by decreasing the transportation process and generating greater economic and industrial flow in the region; and as a final intervention the foundation of a school as a creative network between companies and students of the textile sector to generate learning practices and waste valorization for the development of new markets and a common welfare.

PROJECT TEAM

Paolo Cardorani, Matilde Molari and Marco Tetrai

INSTITUTION

Politecnico di Torino,

Department of Architecture, Italy

Category

System

FACULTY/COURSE ADVISOR

Silvia Barbero and Chiara Battistoni

STAKEHOLDERS

Comero S.p.a. – Wool Mill in Piedmont Region Tintoria Quaregna – Industrial Dyeing in Piedmont Region Biella The Wool Company – Contractor in Piedmont Region