Winner – 1st Prize

Filoskin

Living microfiber made of algae

Solution

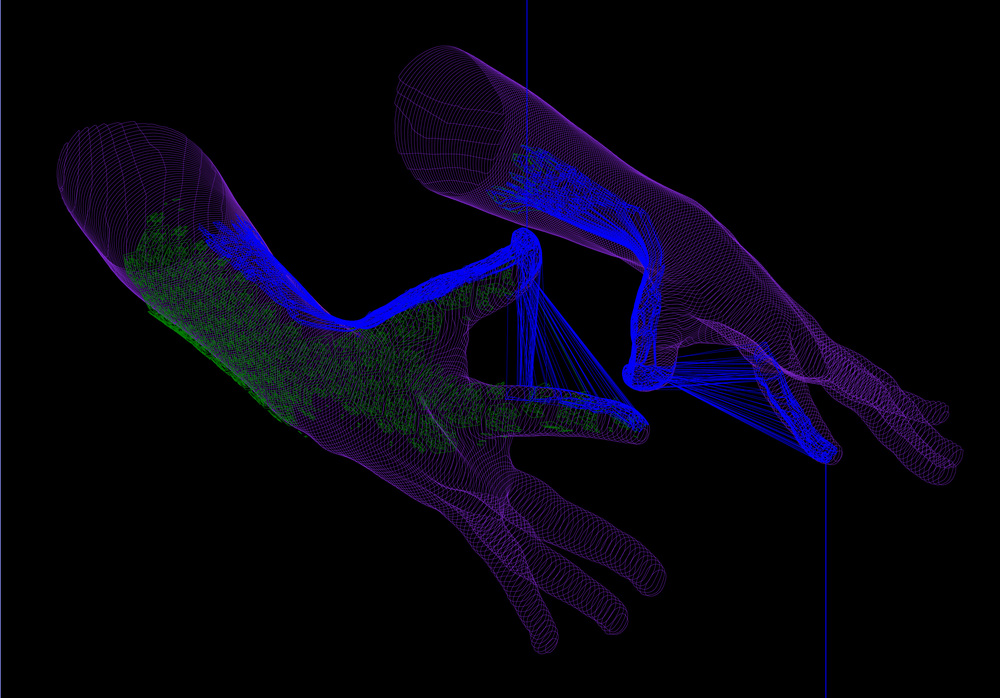

FiloSkin is a speculative product and system that proposes a thread made of H. Pluvialis, a microalga that is capable of producing oxygen, filtering CO2 from the air and responding to changes in the environment by taking on different colors. A symbiosis of nutrient exchange is established for common benefit, in which the organism acquires antioxidants, oxygen and environmental information with colors, while the tissue, through its geometry is able to condense and process CO2 and water vapor from our skin and the surrounding environment. By enabling textiles to interact with our bodies through a symbiotic relationship with the skin, Filoskin might serve to mitigate environmental problems while adapting humans to pollution conditions in the future.

Project Description

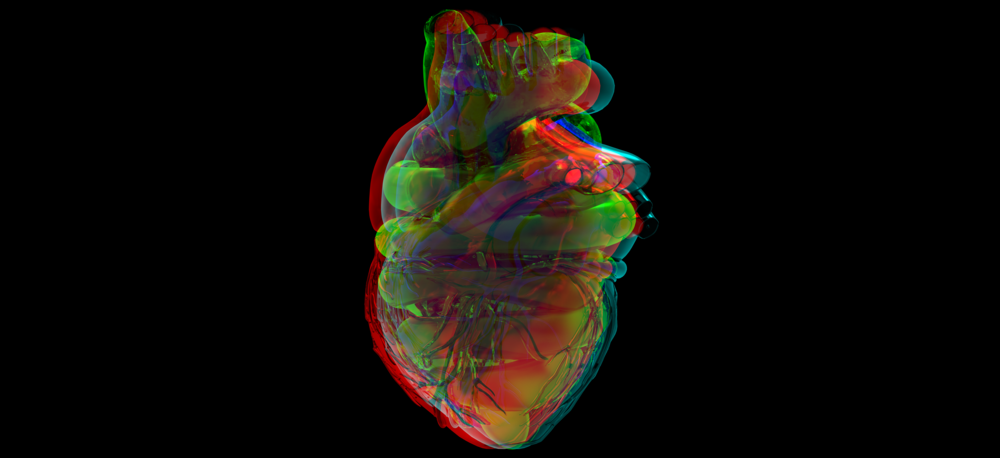

Climate change involves a double approach, developing “integrated” solutions to reduce greenhouse emissions “mitigation”, but also to address the consequences of global warming that will occur in the future, “adaptation”, with the aim to reduce our vulnerability to the harmful effects of climate change. An integrated biomaterial using a particular microalgae called Haematococcus Pluvialis, to create a living membrane in relation to our skin. The production of a biological tissue through the weaving of the algae thread acquires transhumanistic value enters into symbiosis with our skin for an exchange of nutrients and information improving and adapting the organism to pollution conditions. A symbiosis of nutrient exchange is therefore established for a common benefit where our organism acquires antioxidants, oxygen and environmental info with colors, while the tissue, through its geometry is able to condense and process CO2 and water vapor from our skin and the surrounding environment.

The production of a living microfiber able to produce oxygen, antioxidants and filter air from CO2 is an innovative product, but it is able to act in a wide system of solutions to improve environmental quality, from human, ethical and economic interactions. An example is the implementation in recent years of algae cultivation, used in the pharmaceutical, food and energy sectors with low production costs. For this reason, the possible applications of the material can be proposed in various areas, not only membranes to be worn in fashion design, but also for architectural covers that can clean the air and change color, as in outdoor furniture design, objects in close contact with humans in search of a symbiosis. The contrast between anthropocene and the future reality based on natural materials.

Overview of the Solution

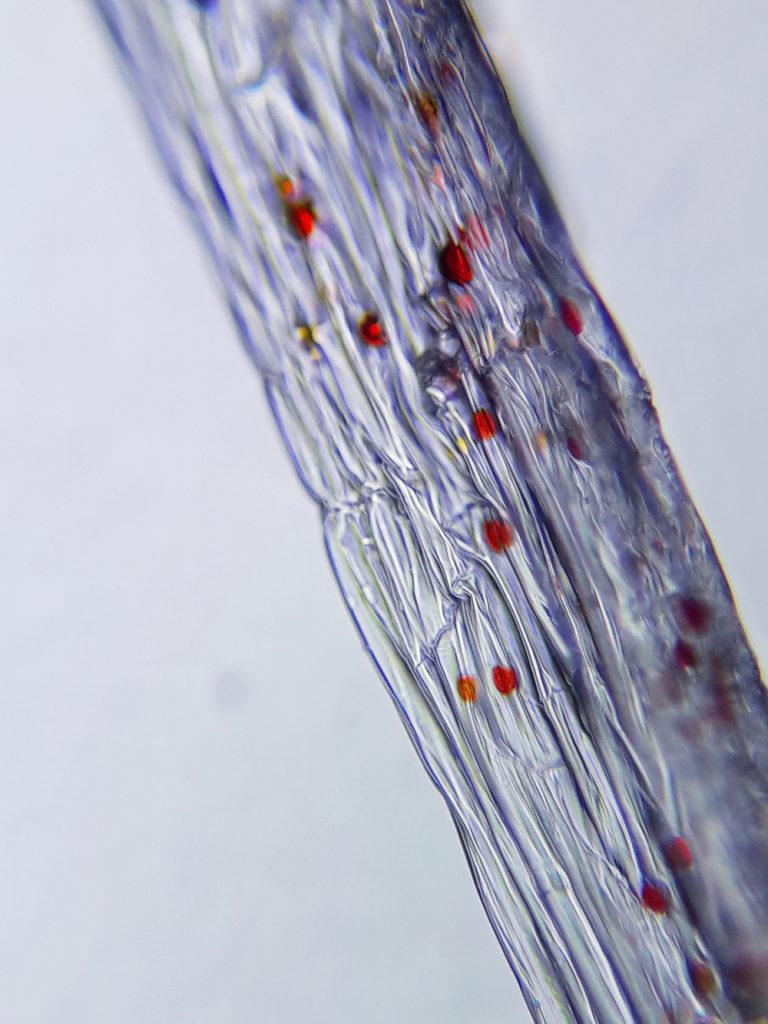

The basic properties of the alga should allow the tissue to change colour, from green to red, depending on environmental conditions constituting a visual environmental sensor quality. Color change occurs for astaxanthin production due to environmental stresses including lack of light or nutrients from a polluted, elevated or low temperature area. What is configured is an extrasensory experience, “dressing” a second living skin composed of green algae. Skin protection and oxygen absorption is the first step that the membrane takes care of, filtering the air and nourishing itself with CO2. But it is in metropolises, cities and areas with a high level of pollution that the membrane activates its properties. Undergoing environmental stress due to a lack of nutrients from the surrounding air, we can observe a change in pigmentation in a few hours, informing us visually of the quality of the air. At this time the algae will begin to produce astaxanthin, antioxidants that our body will take through the skin to rebalance chemically our body. Only a healthy environment can restore the algae to a stable condition, returning to a green pigmentation.

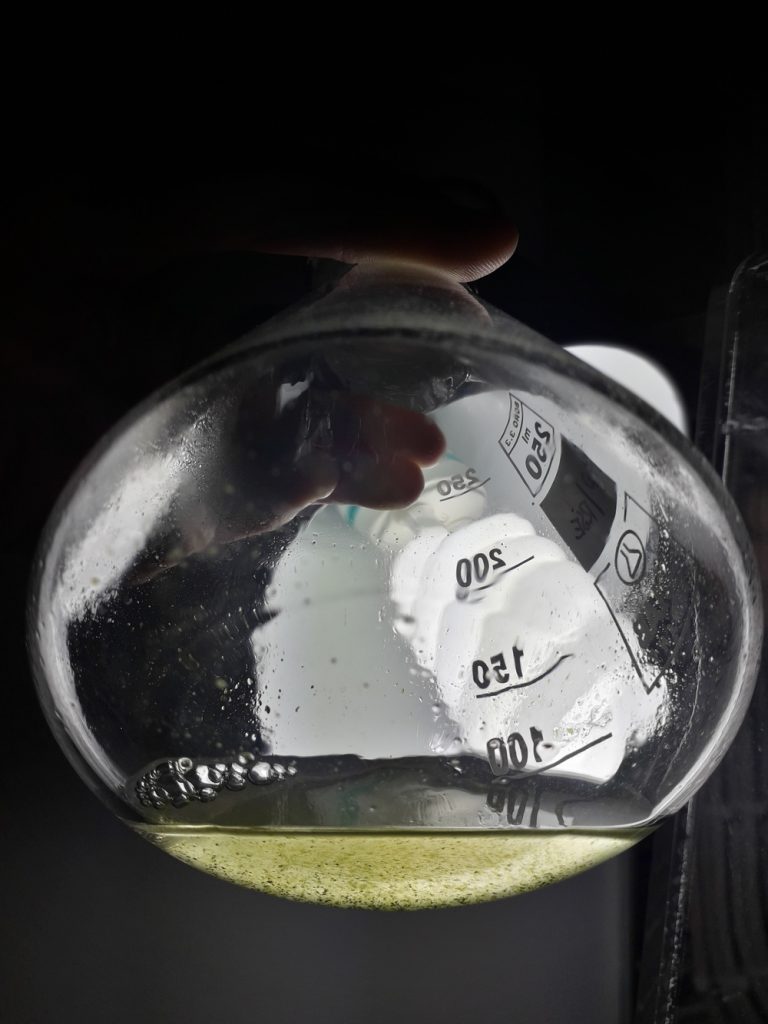

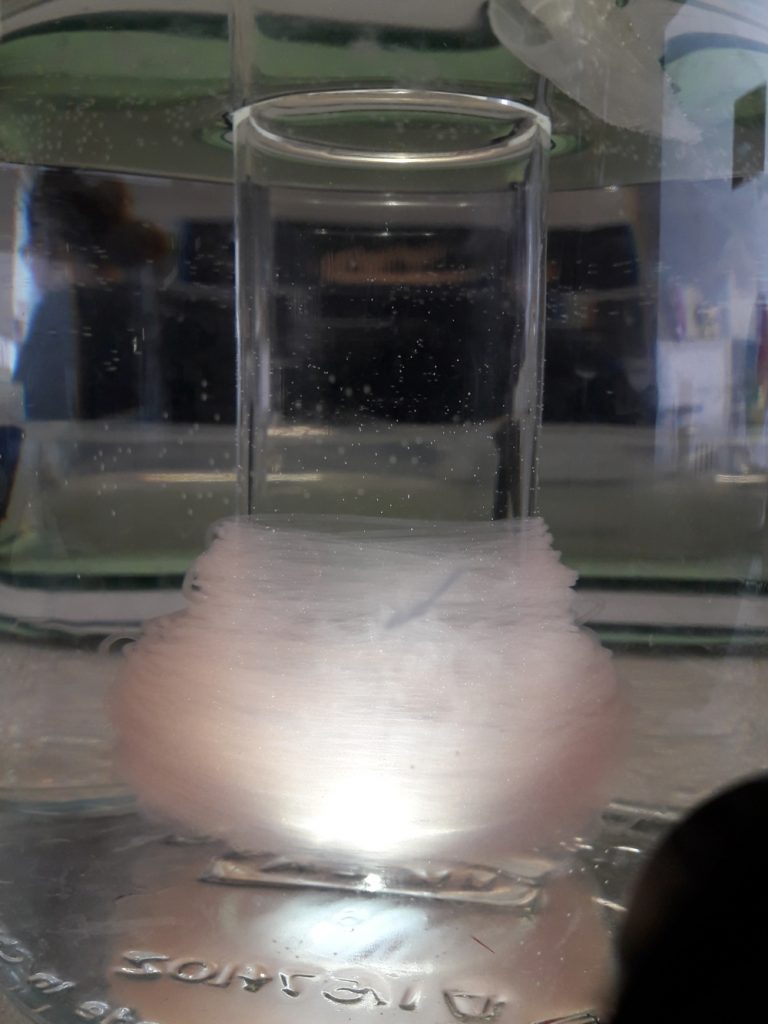

Processing the biomaterial from a liquid state in filiform without compromising the alga inside, it is possible by using alginate characteristics and textile technique “wet spinning”. By replacing and modifying some elements, I build a machine capable of polymerizing alginate in microfibers. It consists of processing a continuous flow of alginate through a needle in a calcium solution with rotary flow, so that the alginate in contact with the calcium solution will instantly polymerize into a filiform thanks to the continuous flow. Extend as much as possible our notions about the relationship nature, man, environment and technology. An eco-sustainable and ethically correct solution for the benefit of both nature and man, looking to the future of materials towards a reality of mutual respect and coexistence, sensible not only to a cleaner world, but in caring for the whole natural sphere in search of symbiosis.

Meet the Winner

Valerio Di Giannantonio

Dear Cumulus Association and Cumulus Committee,

I cannot stress enough how happy and grateful I am for receiving this Prize. I am honored and I thank you all so much for the acknowledgement.

I must say my reaction to the winning was priceless. Naturally, I always hoped to receive the first prize, but just when I read the message, I had to pinch myself couple of times and read it twice!

This recognition made me immensely proud and it mattered to me very much: Cumulus has an innovative way to look at sustainable solution for the future. It shows that we can influence our planet, even with our small projects. If we start from the Product Design, or even better form science and biology, we can make a big impact on the lifecycle of our everyday products. And when we do that, we can be decisive in the shift from linear to circular economy. This is what I wanted to communicate with my project, “Filo Skin” and I am incredibly happy to see an association like Cumulus thinks in the same way that I do and decided to give me the opportunity to bring Filoskin forward.

I thank you all again for the great opportunity. It is was so wonderful to participate to this contest.

I would also like to take the opportunity to thank the Be Open Foundation and Cumulus Secretariat who made the prize possible.

Gratefully yours,

Valerio Di Giannantonio

PROJECT TEAM

Valerio Di Giannantonio

INSTITUTION

Iceland University of the Arts, Iceland

Category

Product/System