Honorable Mention

Algator

Algator is a bioreactor for home-grown algae

Solution

Algator is a bioreactor for home-grown algae. Some species of algae can solve problems of future foods, responding to the population growth and the need for healthy and sustainable food sources. The device allows the owner to participate in a growing process and be closer to nature. Its appearance, which is similar to kitchen supplies, suggests the edible aspect of the jug content. Hidden electronic components ensure an appropriate environment for algae.

Project Description

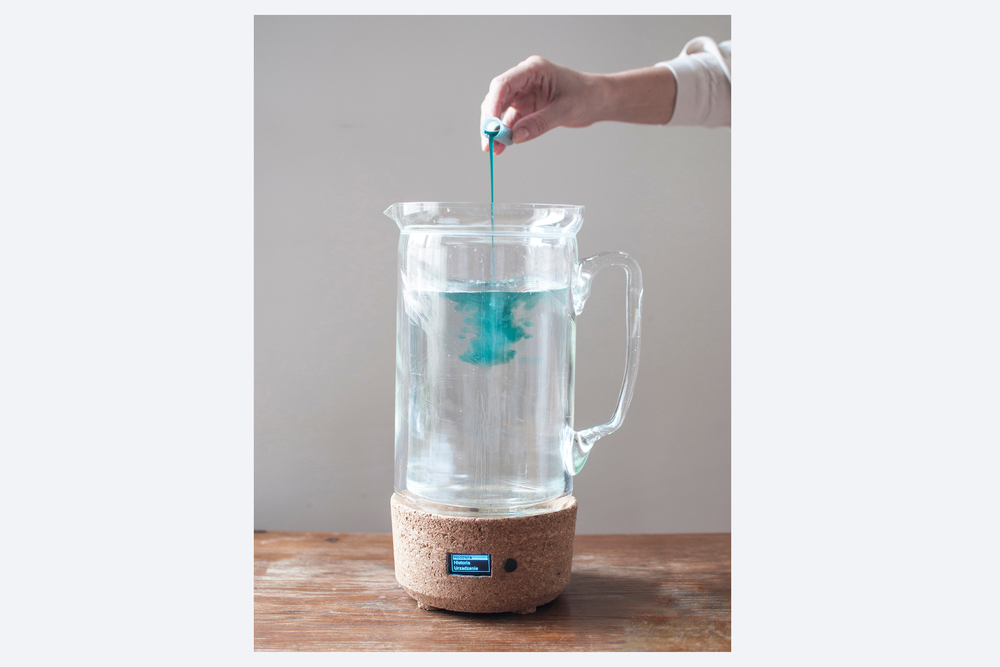

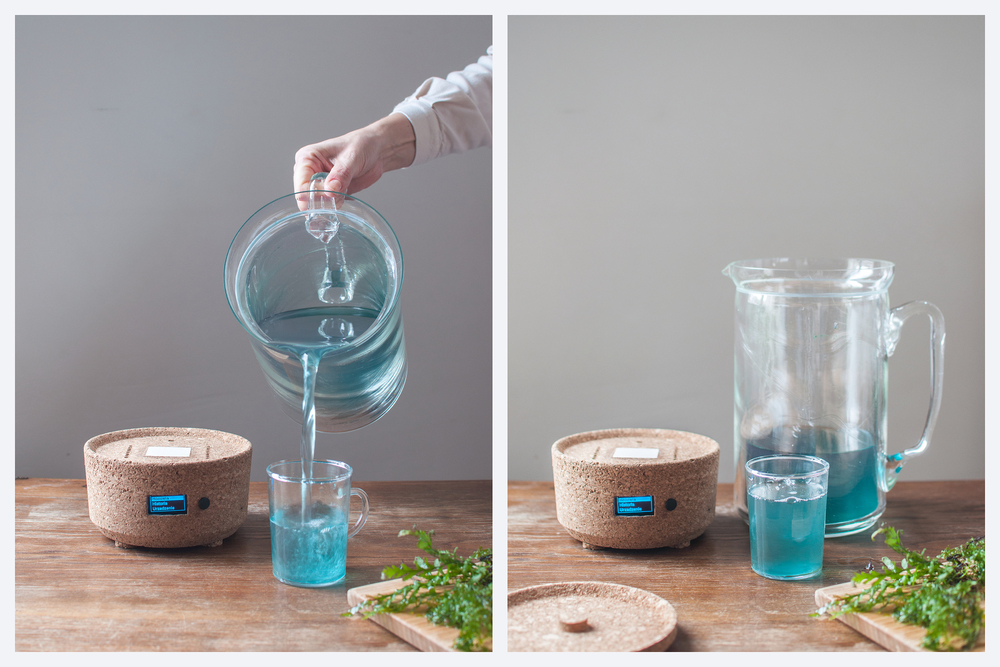

Algator provides algae with the right conditions for growing through the use of electronic components that control the temperature, lighting, water movement and aeration. The device is partly automatic, but gives the user a possibility of feeding and caring for living organisms. When starting the cultivation, distilled water and nutrients are put into the jug while the temperature, light, and aeration are set to pour the algae starter culture. The jug, which is a well-known shape, makes this device friendly and suggestive of a kitchen appliance. This helps to get used to the idea of eating algae. The cork base conceals electronic components and elevates the jug so that the beauty of these unusual organisms can be observed. The materials are ecological and provide the right properties – isolation and water resistance. Algator electronics system is only made of necessary components, which makes it energy efficient and sustainable.

Overview of the Solution

Algator was created from my fascination with algae. These organisms play a vital role in ecosystems, produce half of the oxygen on Earth, and might be crucial for a sustainable future as an energy source in pharmaceuticals and cosmetics, in water remediation, as a fertilizer, animal feed and they can serve as the food of the future for the growing human population. Nutrients content and ecological cultivation make them healthy, sustainable source of food. Algator enables people to grow algae at home and helps them get to know these often underappreciated organisms. People on different diets can benefit from algae species – those on a vegan diet can supplement vitamin B12, others, on a meat diet, will benefit from plant-based micronutrients.

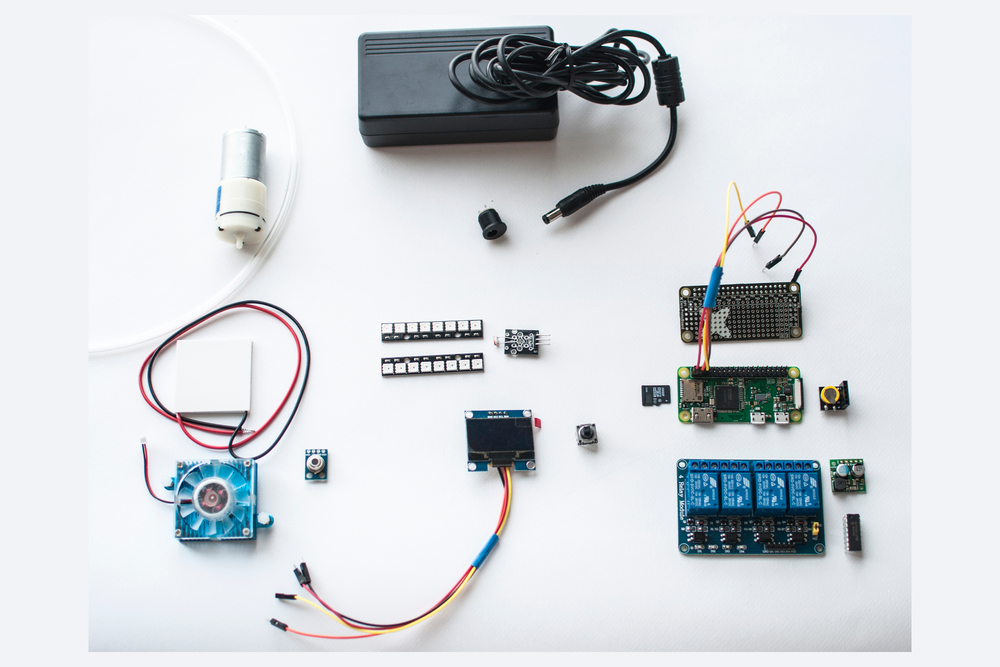

One of the reasons behind this project is to allow users to be closer to nature, which is achieved by allowing for individual cultivation at home. I designed the shape of the device, which is friendly and familiar. We can easily imagine it on the countertop. Due to similarity with kitchen devices, I wanted to highlight the edible purpose of Algator, and encourage people to eat and grow algae. The device provides algae with the right conditions for growing through the use of electronic components that control the temperature (the Peltier plate, radiator, and temperature sensor), lighting (the LEDs and light sensor), and water movement and aeration (the pump).

The second group of components is responsible for the proper functioning of the machine (the microcomputer, relays, etc.) while the third group enables the controlling of the growing process (the screen and button). The device is partly automatic, but gives the user a possibility of feeding and caring for the living organisms. The bioreactor has a capacity of 3l to provide an ergonomic weight. Its 31 cm in height and 15 cm in diameter make it very handy. The materials are selected to provide sustainable properties. The double walls of the glass jug insulate water, reducing power consumption. Cork oak bark is obtained without harming the tree, it is hydrophobic, resistant to biological corrosion and easy to form by pressing cork granules.

The project was developed in consultation with specialists and relied on my practical knowledge of raising seaweed as well as research of algae. I chose components and materials for the economic, functional and technological purpose, to make an environment-friendly device, which gives the users an opportunity to cultivate.

PROJECT TEAM

Ewa Hiller

INSTITUTION

Academy of Fine Arts in Warsaw, Poland

Category

Product

FACULTY/COURSE ADVISOR

Dr. Daniel Zieliński